In a quick one day build, I made a 3D printed wire bending machine. I need a bunch of copper wire bridges with a specific shape, and this machine really makes fast work of it! And it can bend other shapes too…

The STEP and STL files are here:

In a quick one day build, I made a 3D printed wire bending machine. I need a bunch of copper wire bridges with a specific shape, and this machine really makes fast work of it! And it can bend other shapes too…

The STEP and STL files are here:

(continued from part 1)

Time to make some drawings! I took some rough measurements and built a CAD model, to be able to plan out the parts for the conversion:

In this post, we will write a python script for FreeCAD that generates planetary gear assemblies.

Quick one-day build: I had too many ER collets rolling around in the drawer, time for a little bit of cleaning up. I designed a simple collet tray in ViaCAD and printed it on the delta printer:

CAD files : er_trays.zip

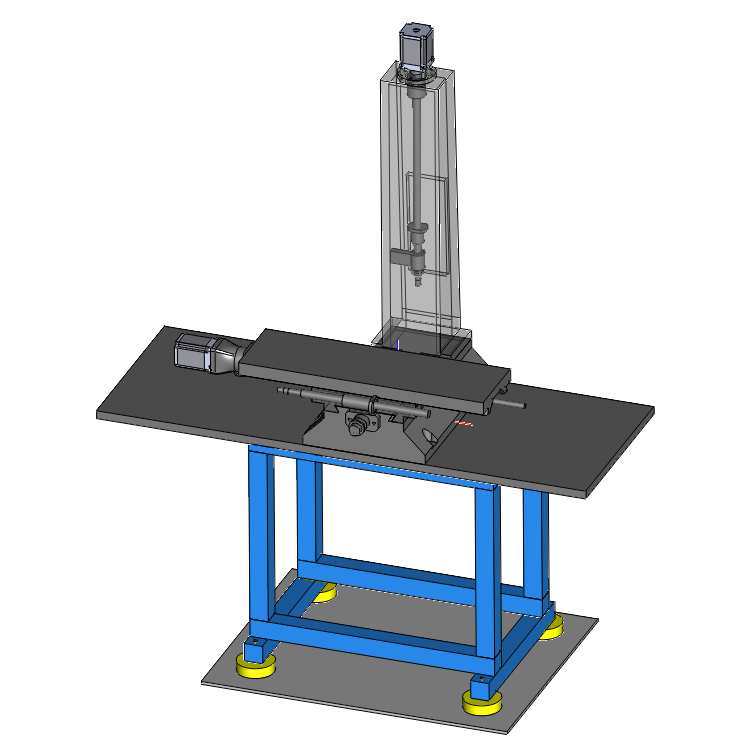

After years of pushing my little X2 Mini-Mill to the limits, and trying to cut aluminium on my large router table, it became clear that I need a bigger machine, that can handle metal with decent precision. And of course it has to be CNC, and it should be a capable beast. Fast, precise, versatile.